LOUISVILLE, Ky.– Ford Electric motor Co. will certainly spend almost $2 billion retooling a Kentucky manufacturing facility to generate electric vehicles that it claims will certainly be a lot more inexpensive, a lot more successful to develop, and will certainly outcompete competing versions.

The car manufacturer’s magnate introduced the brand-new EV technique at Ford’s Louisville Setting up Plant which, after creating gas-powered automobiles for 70 years, will certainly be transformed to produce electrical automobiles.

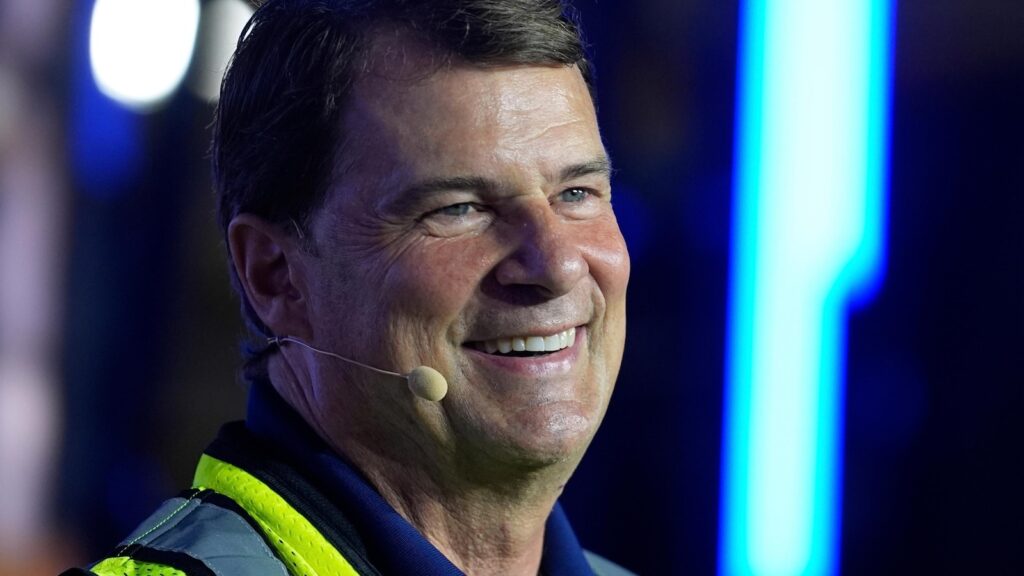

” In our occupations, as auto individuals we’re fortunate if we reach work with one, possibly 2, tasks that actually alter the face of our sector,” chief executive officer Jim Farley informed plant employees in Kentucky on Monday. “And I think today is mosting likely to light the suit as one of those tasks for everyone right here.”

The Huge Detroit car manufacturers have actually remained to shift from inner burning engines to EV modern technology also as Head of state Donald Trump’s management relaxes motivations for car manufacturers to go electrical. Trump’s substantial tax obligation and investing regulation targets EV motivations, consisting of the imminent removal of a credit that conserves customers approximately $7,500 on a brand-new electrical cars and truck.

Yet Farley and various other magnates in the automobile sector claim that electrical automobiles are the future and there is no going back.

The very first EV to roll off the overhauled Louisville production line will certainly be a midsize, four-door electrical pickup in 2027 for residential and worldwide markets, the firm claimed Monday.

The brand-new electrical vehicles will certainly be powered by lower-cost batteries made at a Ford manufacturing facility in Michigan. The Detroit car manufacturer formerly introduced a $3 billion financial investment to develop the battery manufacturing facility.

The car manufacturer sees this as a “Design T minute” for its EV company– a referral to advanced modifications on the assembly line led by the firm’s creator, Henry Ford, when it started producing automobiles from a manufacturing facility greater than a century earlier. Farley claimed the modifications will certainly will overthrow just how electrical automobiles are made in the united state

” It stands for one of the most transformation on just how we layout and just how we develop automobiles at Ford given that the Model-T,” Farley claimed.

The firm claimed it will certainly make use of a global system and manufacturing system for its EVs, basically the foundation of a lorry that can be used throughout a variety of versions.

The Louisville manufacturing facility– a couple of Ford setting up plants in Kentucky’s biggest city– will certainly be overhauled to reduce manufacturing expenses and make setting up time quicker as it’s prepared to create electrical automobiles.

The outcome will certainly be “an inexpensive electrical lorry that we anticipate to be successful,” Farley claimed in a meeting with The Associated Press in advance of the statement. “This is an instance people revitalizing our united state plants with one of the most modern-day production strategies.”

The brand-new system makes it possible for a schedule of inexpensive automobiles to be generated at range, Ford claimed. It will certainly decrease components by 20% versus a common lorry, with 25% less bolts, 40% less workstations dock-to-dock in the plant and a 15% faster setting up time, Ford claimed. The typical production line will certainly be changed right into an “setting up tree” at the Louisville plant, it claimed. As opposed to one lengthy conveyor, 3 sub-assembly lines will certainly run concurrently and afterwards collaborate, it claimed.

Various other requirements for the midsize electrical vehicle– including its expose day, beginning cost, EPA-estimated battery array, battery dimensions and cost times– will certainly be introduced later on, the firm claimed. Ford exposed in its launch that the vehicle will certainly have a targeted beginning cost of concerning $30,000.

Ford claimed its financial investment in the Louisville plant will certainly protect 2,200 per hour work.

Kentucky Gov. Andy Beshear claimed Monday that the car manufacturer’s prepare for the Louisville plant will certainly enhance a greater than century-old collaboration in between Ford and the Bluegrass State.

” This statement not just stands for among the biggest financial investments on document in our state, it likewise enhances Kentucky’s setting at the facility of EV-related advancement and strengthens Louisville Setting up Plant as a fundamental part of Ford’s future,” Beshear claimed.

Ford claimed its mixed financial investment of concerning $5 billion at the Kentucky setting up plant and Michigan battery plant is anticipated to produce or protect almost 4,000 straight work in between both plants while enhancing the residential supply chain with loads of brand-new U.S.-based distributors.

Ford formerly forecast weaker earnings growth for this year and additional losses in its electrical automobiles company as it functions to manage expenses. Design e, Ford’s electrical lorry company, published a full-year loss of $5.08 billion for 2024 as profits dropped 35% to $3.9 billion.

Ford’s brand-new EV technique comes as Chinese automakers are promptly broadening around the world, providing reasonably inexpensive electrical automobiles.

” We’re not in a race to develop one of the most electrical autos,” Farley informed the AP when inquired about competitors from China. “We remain in a race to have a lasting electrical company that pays, that consumers like.

” And this brand-new lorry integrated in Louisville, Kentucky, is mosting likely to be a better option to anything that anybody can purchase from China,” he included.